Catching up

It’s been a while since my last post. In the last few months, I’ve been preparing for my second project, which is a women’s jogger. Before actually making any clothing, I finished reading a book in Chinese called “How to Become a Fashion Designer.” The book thoroughly demonstrates the history of clothing, including the reasons and impacts on society at different eras. It covers topics throughout the entire clothing-making process, from finding insights from various resources and selecting fabrics to pattern making, sample making, final production, and the sales and promotion phase of brands or final products.

Therefore, this project has become an opportunity for me to practice pattern making. To be honest, there are definitely easier ways to make clothing, such as using your existing clothing as a pattern. This approach saves time as you don’t need to create the pattern from scratch. I highly recommend this method if you decide to pursue sewing as a hobby. However, for me, I want to practice making patterns from scratch to gain a comprehensive understanding of the process.

Pants Design

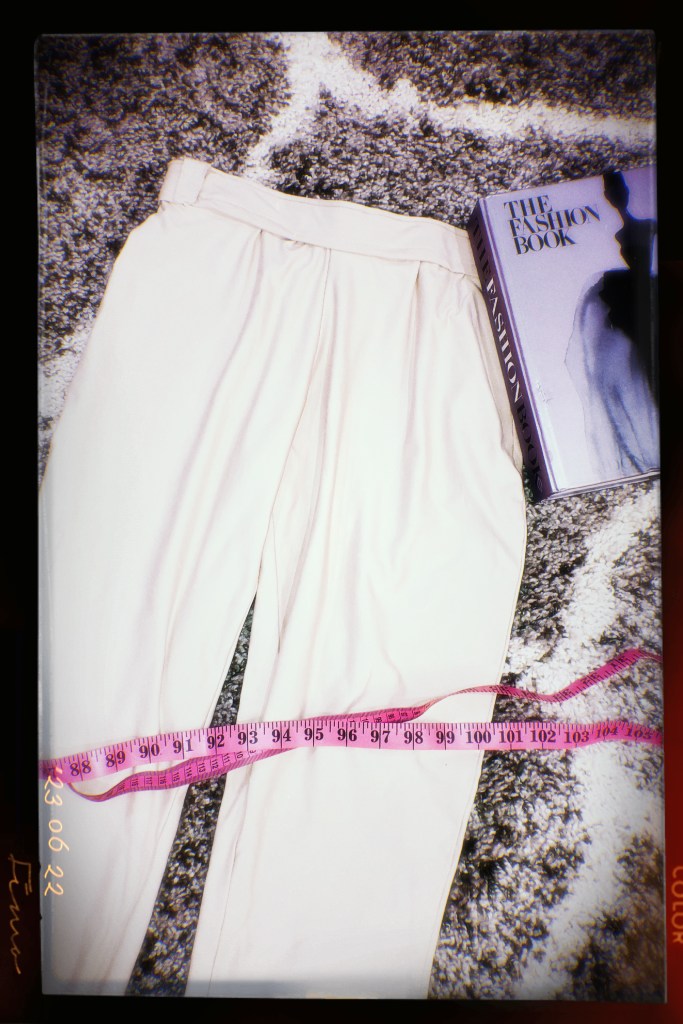

Coming up with ideas for the pants and designing them was a quick process. Based on the client’s request, I aimed to create something similar to Lululemon’s Ready to Rulu. Although the final product doesn’t have the exact same look, I’m still proud of it as my first sewn pair of pants.

Fabric

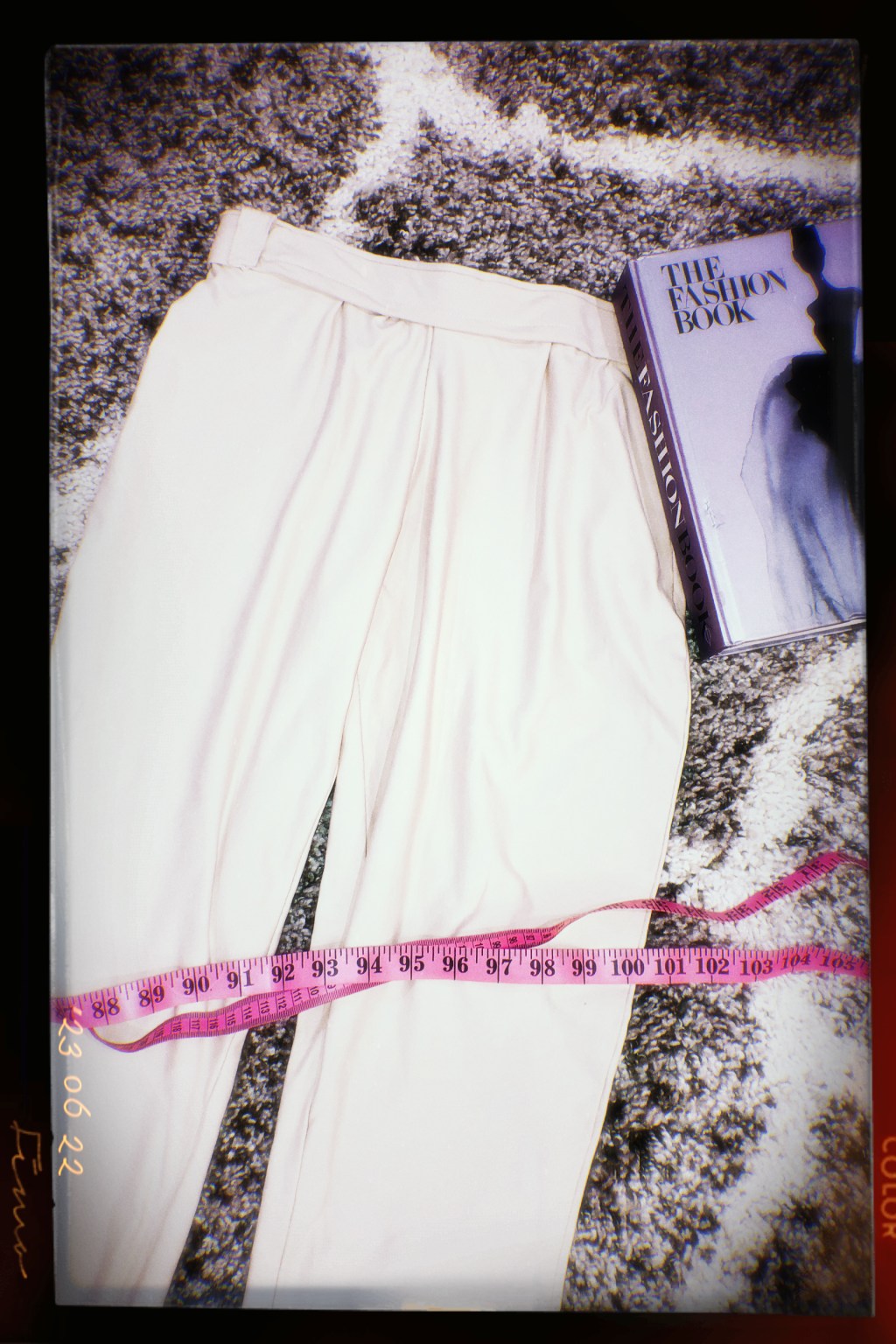

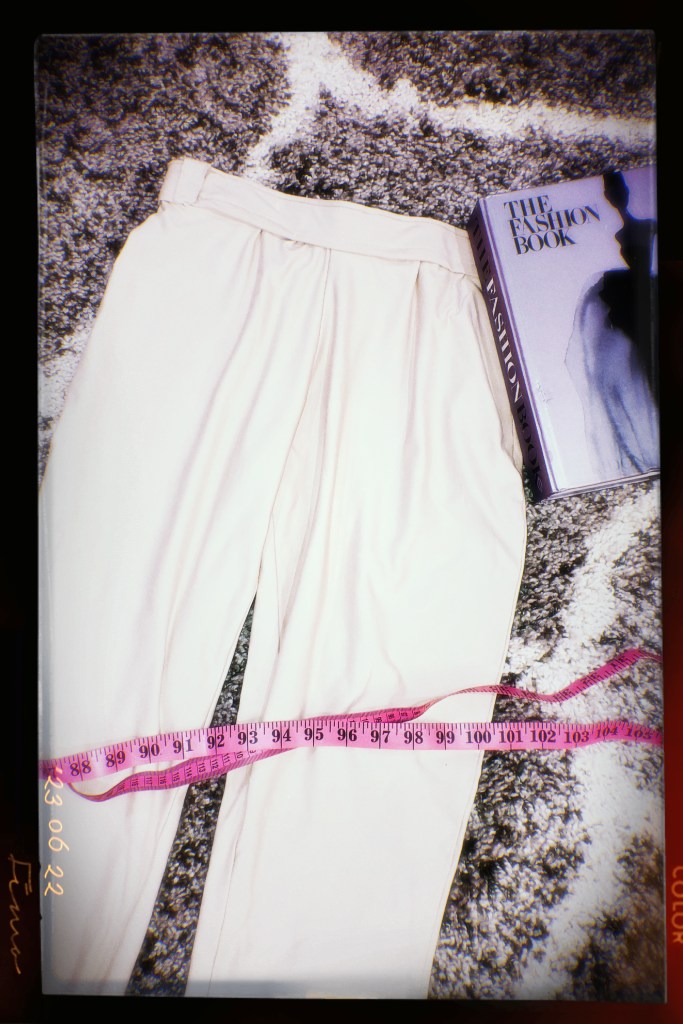

It’s been a while since I purchased the fabric. The goal for the pants was to ensure that the client feels lightweight, cool, and comfortable. If I remember correctly, it was a blend of cotton, polyester, or nylon in a beige color. In the future, I should make a note of the fabric types I purchase. Additionally, I used elastic for the waistband.

Pattern Making

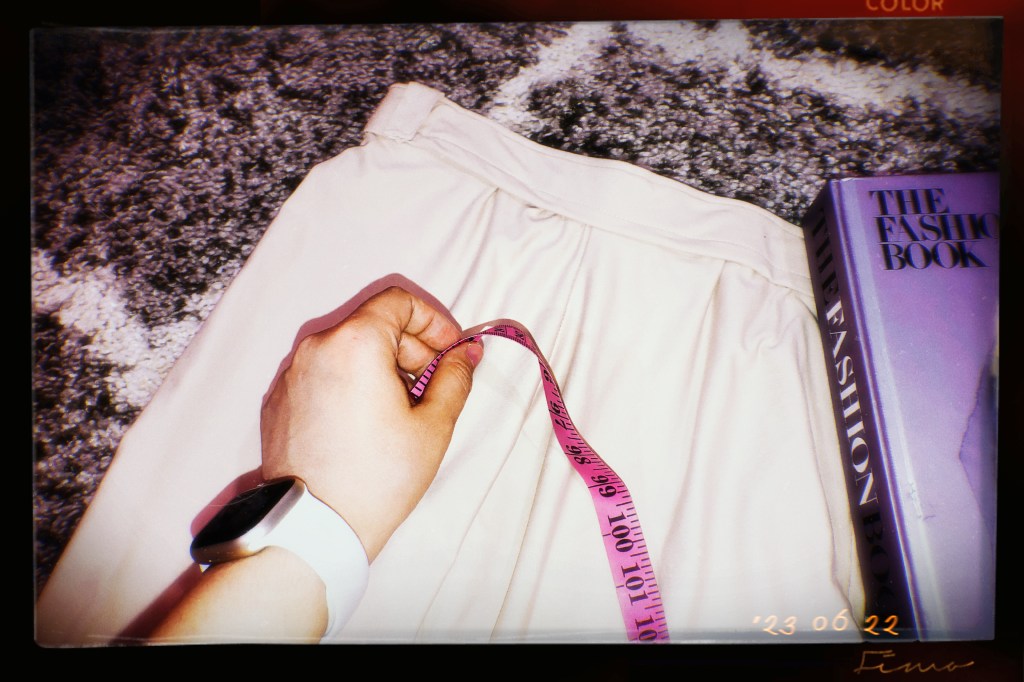

This phase took the most time. I initially used muslin fabric to create the pattern. I went through two iterations of the pattern-making process. In the first round, I realized that the seating area part wasn’t tight enough. In the second round, I made adjustments, and even though there were two rounds of drawing the pattern and having my client try them on, I still found that the inseam line was slightly off in the final product. There is definitely room for improvement.

During the pattern making process, I found this video is quite helpful. Feel free to check it out. How to draft a men’s pant pattern … and fix fit issues!

Piece Them All Together

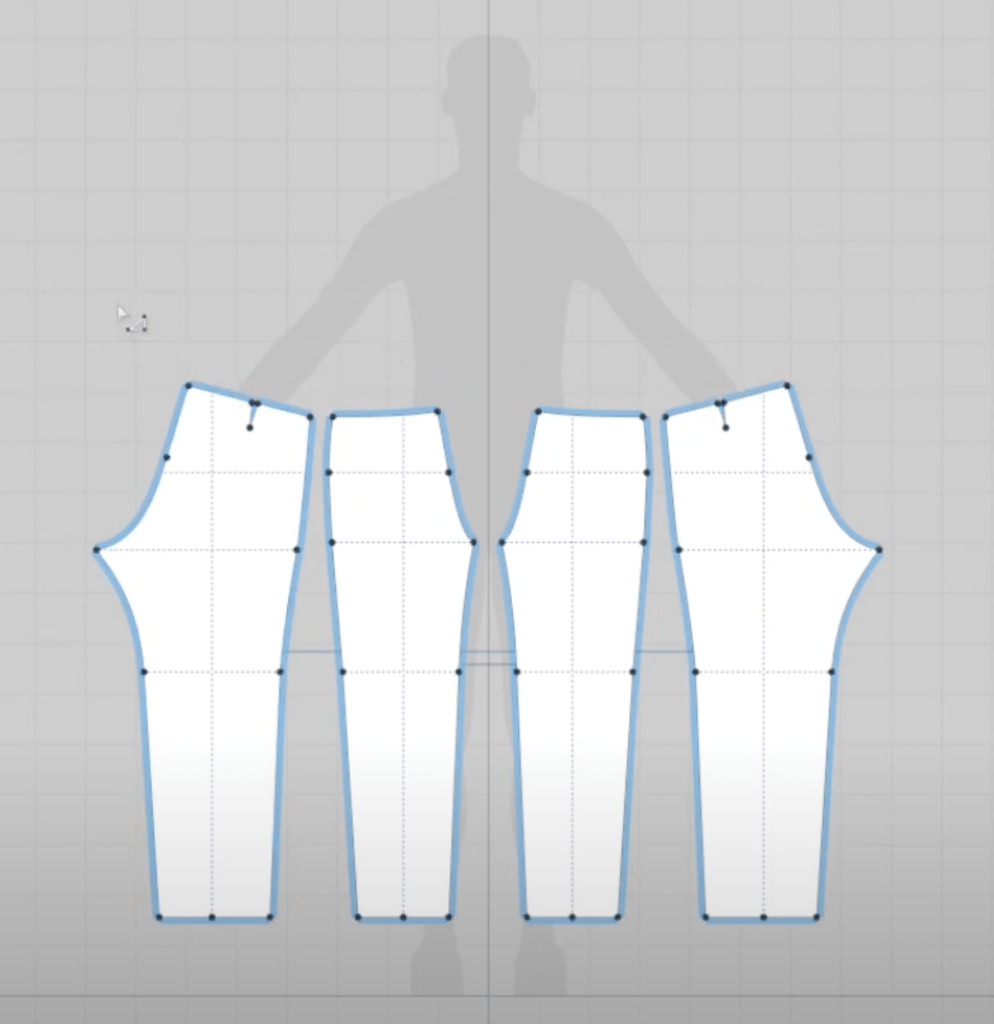

The last step is to cut the fabric based on the pattern and piece them together. There are four pieces in total: two front pieces in the middle and two back pieces on each side. (see below)

Final Product

I hope you find the article interesting and enjoyable. I look forward to sharing more projects with you in the future!